At present, many consumers are turning their attention to silicone products that are harmless to health, high temperature resistance, and cold resistance, such as silicone water cups, silicone fresh-keeping boxes, silicone wristbands, etc.

In fact, in the textile printing and dyeing processing industry, silica gel, a non-toxic and non-polluting material, has always been concerned by some companies. At the same time, the editor also learned that some enterprises have applied it to the actual production process, becoming a new competitiveness in the textile processing industry and bringing new profit growth points for enterprises.

According to the senior person in charge of the silicone printing field, "The core of the silicone printing process is to use green and environmentally friendly printing silicone materials, that is, in the printing process of printed textiles, printing silicone is used to replace traditional printing pastes such as glue and thermosetting inks." For example, we Clothing, shoes and hats, sports/microwave oven gloves, and silicone printing that come into contact with in daily life have many advantages such as washing resistance, light resistance, non-bleaching, strong performance, good decorative effect, and harmless to the human body. Function has become the first choice in the textile printing industry.

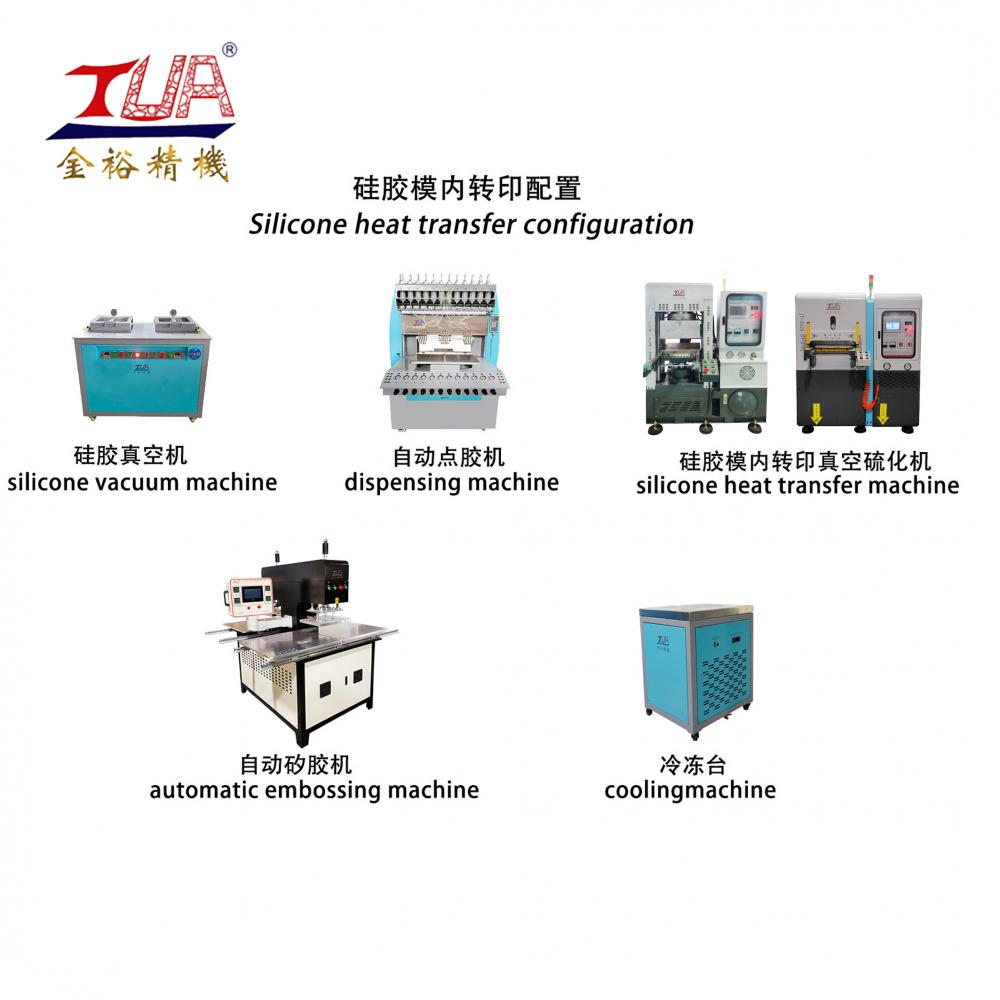

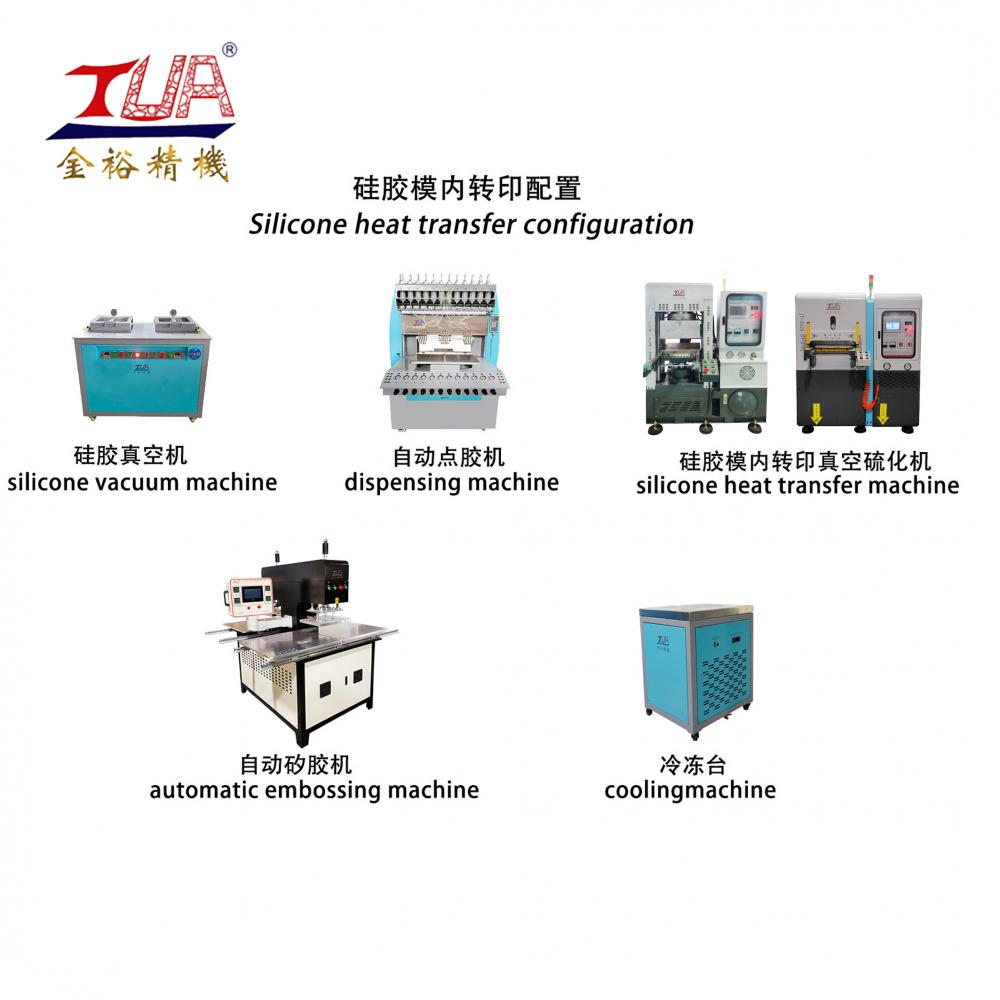

Below we introduce the characteristics and application fields of silicone embossing and in-mold transfer printing silicone respectively.

Silicone Embossing

Silicone Embossing

Silicone embossing is to use liquid silicone, put the liquid silicone into the pattern mold, and then use the Silicone Embossing Machine to heat the silicone and firmly adhere to the surface of the cloth. Colored silicone embossing is also available, supporting multiple effects (bright/matte, straight/rounded).

With its non-slip, waterproof, high and low temperature resistance, health care function, and decorative function, it is mostly used in various non-woven fabrics, genuine leather, cowhide, waterproof nylon/bag cloth.

Silicone mold transfer ironing

The printing rubber head is to use the pattern on the metal mold as the carrier to transfer the pattern on the mold to the product. This process is mainly to make the silicone trademark label through a Dispensing Machine and a Hydraulic Press Machine, and then directly transfer it on the clothing fabric through a Silicone Embossing Machine. Silicone printing requires excellent quality, no impurities, no burrs, good resilience, strong adhesion, not easy to fall off, and clear embossed patterns.

It is mainly used for 3D effect silicone products with irregular patterns such as toys, craft gifts, stationery, clothing trademarks, shoes and hats trademarks, luggage trademarks, communication equipment, mother and baby products, kitchen utensils, and home decoration.

With the integration of the international economy, people's requirements for the quality of life are getting higher and higher. I believe that more and more brands will choose silicone printing.