Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

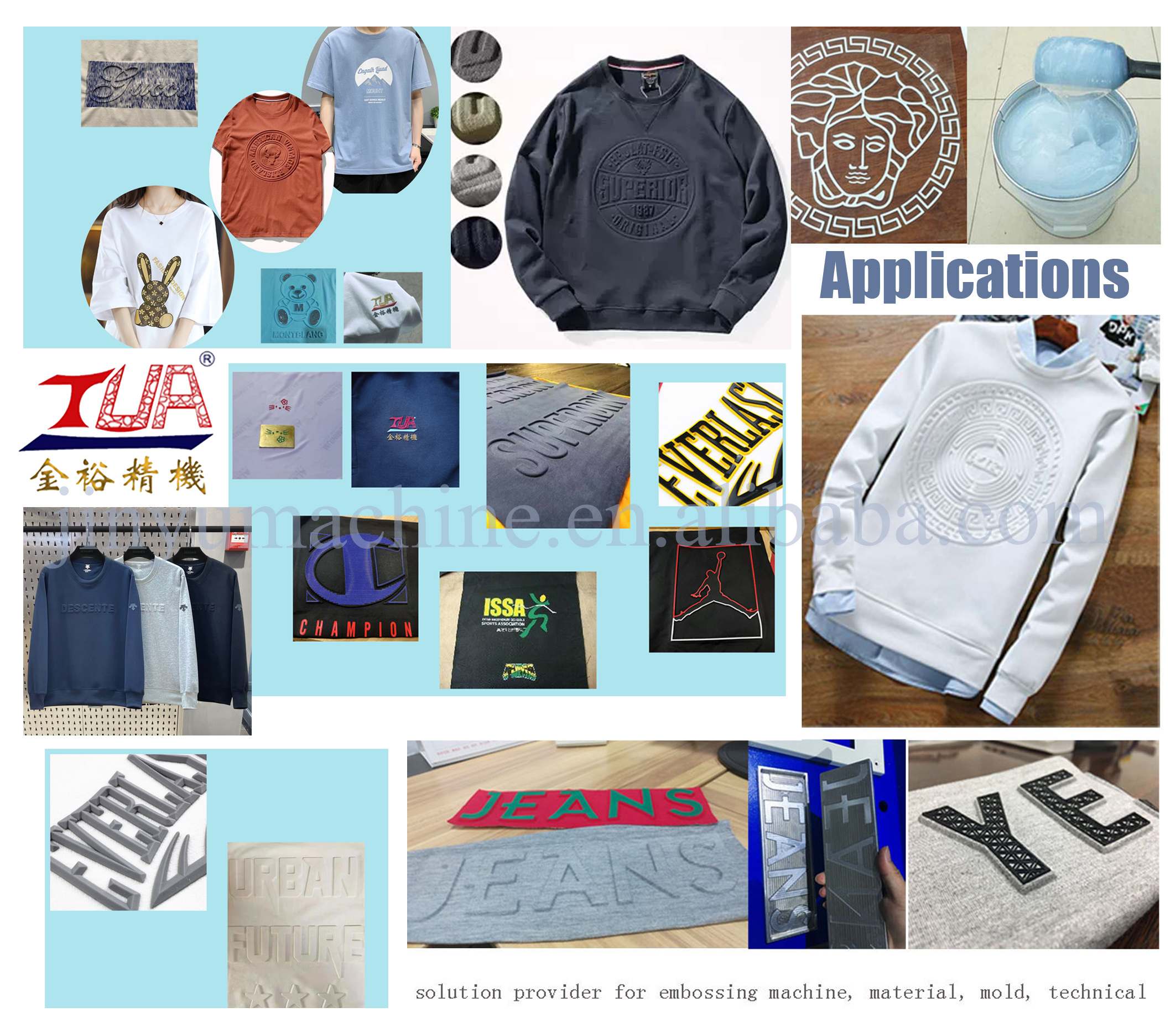

Abstract: This article introduces the screen printing process of silicone rubber, analyzes the difference between it and ordinary screen printing process, explains its technical characteristics, and summarizes its own opinions on technical control. Abstract: This article introduces the difference between the silk screen printing process of silicone rubber and the direct 3D concave-convex embossing process of silicone rubber.

Keywords: Silicone embossing machine, screen printing machine, 3D concave-convex embossing embossing machine, full automatic embossing machine.

With the rapid development of the communication and electronic industries, the production of rubber keys has also developed into a mature technology. There are many kinds of printing processes, such as silicone 3D embossing printing, screen printing, ink color printing, etc.

1. Screen printing process

There are many methods of screen printing plate making, mainly photolithography, that is, the photosensitive glue is directly applied to the screen, and a photosensitive film of a certain thickness is dried to form a graphic carrier. The process flow is: more steps

Screen selection→frame selection→stretching→screen washing→drying→latex coating→exposure→development→printing

2. Silica gel 3D concave-convex embossing process

It's very simple, just prepare liquid silicone, interlining cloth, screen frame, mold, and a Silicone Embossing Machine. Process flow:

First, place the interlining cloth of the cut size under the screen, and then spread the liquid silicone evenly on the screen to make it soak into the interlining.

The second, put the mold into the working table of the machine, put the garments and fabrics to be embossed on the mold, and then spread the smeared interlining cloth.

Last, start the Embossing Machine and shape in a few seconds. It is necessary to set parameters in advance according to different products, such as oil pressure, temperature, time, etc.

October 14, 2024

September 18, 2024

September 11, 2023

July 26, 2023

July 24, 2024

June 06, 2024

この仕入先にメール

October 14, 2024

September 18, 2024

September 11, 2023

July 26, 2023

July 24, 2024

June 06, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.